Table of Contents

1. Introduction

When industries require a material that can withstand extreme heat and corrosion, Stainless Steel 310S often tops the list. Known for its high chromium and nickel content, SS 310S is a heat-resistant alloy designed for elevated temperature applications. It combines strength, durability, and oxidation resistance, making it an essential material in furnaces, petrochemical plants, and power generation equipment.

In this blog, we’ll explain what Stainless Steel 310S is, its composition, properties, benefits, and the industries where it is commonly used.

2. What is Stainless Steel 310S?

Stainless Steel 310S is an austenitic stainless steel grade with 25% chromium and 20% nickel, making it highly resistant to oxidation and scaling even at high temperatures (up to 1100°C).

The “S” in 310S indicates its low carbon content, which prevents carbide precipitation during welding. This improves its weldability and corrosion resistance compared to standard SS 310.

In simple words, SS 310S is a heat-resistant alloy ideal for high-temperature applications like furnaces, kilns, and power plants.

3. Stainless Steel 310S Chemical Composition

| Element | Percentage (%) |

|---|---|

| Chromium (Cr) | 24.0 – 26.0 |

| Nickel (Ni) | 19.0 – 22.0 |

| Carbon (C) | ≤ 0.08 |

| Manganese (Mn) | ≤ 2.0 |

| Silicon (Si) | ≤ 1.5 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.03 |

| Iron (Fe) | Balance |

Why this matters:

- High Chromium → boosts oxidation resistance.

- High Nickel → adds strength at elevated temperatures.

- Low Carbon (310S) → prevents carbide precipitation, improving weldability.

4. Key Mechanical Properties of SS 310S

| Property | Value |

|---|---|

| Density | 8.0 g/cm³ |

| Melting Point | 1400–1450 °C |

| Tensile Strength | 520 MPa (min) |

| Yield Strength | 210 MPa (min) |

| Elongation | 40% (min) |

| Hardness | 225 HB (max) |

These mechanical properties make SS 310S suitable for heat-intensive and corrosive industrial environments.

5. Stainless Steel 310 vs 310S: What’s the Difference?

Many buyers search for SS 310 vs SS 310S, so here’s a clear comparison:

| Feature | SS 310 | SS 310S |

|---|---|---|

| Carbon Content | Higher (≤0.25%) | Lower (≤0.08%) |

| Weldability | Moderate | Excellent |

| Resistance to Carbide Precipitation | Lower | Higher |

| Best Use | High-temp parts without welding | High-temp parts requiring welding |

6. Where is Stainless Steel 310S Used?

Stainless Steel 310S is widely used in industries where heat and corrosion resistance are critical:

- Furnace Equipment → radiant tubes, conveyor belts, burner parts.

- Petrochemical Industry → refinery piping, catalytic converters, process equipment.

- Power Plants → boilers, superheater tubes, heat exchangers.

- Food Processing → sterilizers and equipment exposed to high heat.

- Automotive & Aerospace → exhaust systems, jet engine parts.

- Cement & Steel Plants → kiln linings, rotary kilns, heat-treatment trays.

7. Advantages of Stainless Steel 310S

- Outstanding Heat Resistance – performs well up to 1100°C.

- Oxidation & Scaling Resistance – stable under continuous high-temperature exposure.

- Excellent Weldability – thanks to low carbon content.

- Corrosion Resistant – resists acids, alkalis, and oxidation.

- Durability – long-lasting, even in extreme conditions.

Stainless Steel 310S is a premium high-temperature alloy with excellent resistance to oxidation, scaling, and corrosion. Its low carbon content makes it highly weldable and reliable, especially in industries like furnaces, petrochemicals, power plants, and automotive sectors.

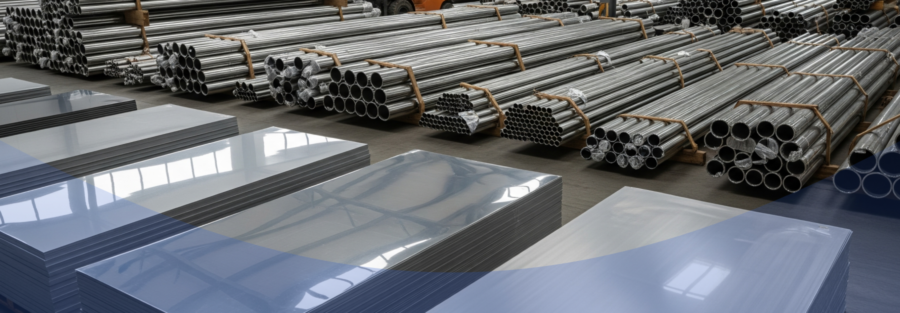

At Riyaarth Overseas, we supply top-quality Stainless Steel 310S sheets, plates, pipes, and fittings that meet global standards. Contact us today to source materials that match your industrial needs.

8. FAQs

SS 310S is commonly used in furnaces, boilers, heat exchangers, and high-temperature industrial equipment.

SS 310S has a lower carbon content, making it more weldable and resistant to carbide precipitation.

In the annealed condition, SS 310S is generally non-magnetic, but it may show slight magnetism after cold working.

While SS 310S has good corrosion resistance, for chloride-rich environments, SS 316 is preferred.