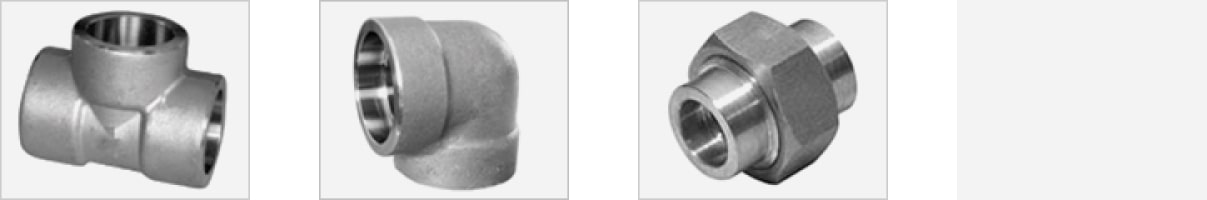

Socket-Weld-Fittings

Riyaarth Overseas excels as a leading manufacturer and exporter of high-quality forged socket weld fittings. Crafted in compliance with ASME B16.11, our range includes Stainless Steel, Carbon Steel, Alloy Steel, and other specialty materials. These fittings are essential components in a variety of demanding industrial applications across sectors such as petrochemicals, power generation, shipbuilding, dairy, breweries, wastewater treatment, and pharmaceuticals.

Product Range and Specifications

Our extensive catalog features a diverse selection of socket weld fittings, including:

- Elbows (90 Degrees and 45 Degrees)

- Tees

- Crosses

- Unions

- Couplings (Full and Half)

- Caps

- Bos

- Outlets (Welding Outlet, Insert)

Pressure Ratings: Available in class 3000, 6000, and 9000, suitable for various operational pressures.

Size Range: From 1/8″ up to 4″ (DN6 to DN100), accommodating a wide range of pipeline diameters.

Materials and Standards

- Stainless Steel Grades: ASTM A182 F316L, F304L, F309S, F310S, F317L, and more.

- Carbon Steel: ASTM A105, A350 LF2.

- Alloy Steel and Others: Including Duplex, Nickel Alloys, and Low Temperature Carbon Steel.

High Pressure Socket Weld Forged Fittings

| Pressure Class | 3000LBS, 6000LBS, 9000LBS |

| Products | Elbow 90 Degree, Elbow 45 Degree, Tee, Cross, Union, Coupling, Half Coupling, Cap, Boss, Outlet, Welding Outlet, Insert |

| Dimension Specifications | ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Size | 1/8″~4″ (DN6~DN100) |

Compliance and Quality

- All materials conform to ASME A182 for stainless steel and ASTM/ASME A105/SA105 for carbon steel.

- Dimensions of all socket weld fittings adhere to ASME B16.11 specifications.

Value-Added Services To enhance product longevity and performance, we offer:

- Hot Dipped Galvanizing

- Epoxy & FBE Coating

- Electro Polishing

- Sand Blasting

- Threading and Soldering

Quality Assurance and Packaging

Riyaarth Overseas commits to the highest standards of quality, with each fitting undergoing stringent inspections at every production phase. They are checked for conformity with ASTM, ASME, MSS, DIN, EN, and JIS standards. Our fittings are also available with:

- EN 10204 3.1B Manufacturer Test Certificates

- 100% Radiography Test Reports

- Third-Party Inspection Reports

Marking and Packaging Every socket weld fitting is marked with the grade, lot number, size, and pressure class. Standard export packaging in wooden cases ensures safe and secure delivery worldwide. Custom marking is available upon request.

Applications

Forged socket weld fittings are pivotal in systems requiring robust and leak-proof piping solutions. They are particularly favored in applications where space is limited and high-integrity connections are crucial.

Enhance your industrial piping systems with Riyaarth Overseas’s forged socket weld fittings. Contact us today to explore our products and find tailored solutions that meet your exact specifications for reliability and performance.

FAQ's

Forged fittings provide exceptional strength and durability, ideal for high-pressure applications and minimizing leakage.

Selection depends on the service conditions like temperature, pressure, and media type. Our experts can help guide you to the right material choice based on your specific operational needs.

Yes, we can customize fittings to meet unique system requirements, including specific dimensions, pressure classes, and material grades.

Products

Industry We Serve

- Oil & Gas industries

- Chemical process industries

- Pump and valve in high pressure component

- Food industries

- Pulp and paper industry

- Aerospace industry

- Power plant

- Mechanical component

- Sugar industry

- Cement industry