Super Duplex Stainless Steel Flanges

Super duplex stainless steel flanges are designed to meet the toughest demands of industries that require excellent strength, corrosion resistance, and durability. With higher chromium, molybdenum, and nitrogen content, super duplex flanges are ideal for applications exposed to aggressive environments, such as offshore drilling, chemical processing, and desalination plants.

Key Benefits of Super Duplex Stainless Steel Flanges

- Superior Corrosion Resistance: Super duplex stainless steel provides exceptional resistance to pitting, crevice corrosion, and chloride stress corrosion cracking, essential for marine and industrial applications.

- Enhanced Strength: Super duplex flanges are nearly twice as strong as standard austenitic stainless steel, making them suitable for high-stress applications.

- Cost Efficiency: Despite their higher initial cost, super duplex flanges provide long-term savings due to reduced maintenance and extended service life.

- Weldability and Durability: Super duplex stainless steel has excellent weldability and high resistance to cracking, ensuring a reliable and durable connection.

- High Fatigue and Abrasion Resistance: Super duplex flanges withstand high-stress and abrasive conditions, ideal for heavy-duty industrial use.

Grades of Super Duplex Stainless Steel for Flanges

- Super Duplex 2507 (UNS S32750): Known for its superior corrosion resistance and strength, especially in chloride and acidic environments.

- Super Duplex 32760 (UNS S32760): Contains added elements like tungsten and copper for enhanced corrosion resistance, making it suitable for harsh offshore and petrochemical environments.

- Other Grades: Additional super duplex grades, such as S32707, offer specific performance attributes for unique applications.

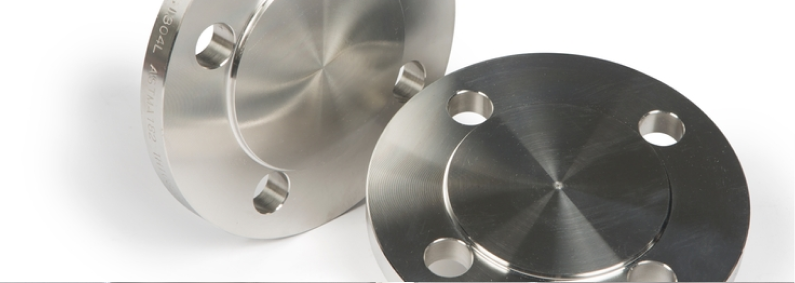

Types of Super Duplex Stainless Steel Flanges

We provide a complete range of super duplex stainless steel flange types for various applications:

- Weld Neck Flanges: Provides a seamless, strong connection to the pipe and is ideal for high-pressure applications.

- Slip-On Flanges: Economical and easy to install, commonly used in low-pressure applications.

- Blind Flanges: Used to close off the end of a piping system, allowing easy access for future expansions or maintenance.

- Socket Weld Flanges: Suitable for small-diameter, high-pressure pipes and systems.

- Threaded Flanges: No welding required, ideal for low-pressure applications with external threads.

- Lap Joint Flanges: Used with stub ends and designed for systems requiring frequent dismantling and inspection.

- Orifice Flanges: Designed for flow measurement applications, with machined holes for precision flow devices.

Applications of Super Duplex Stainless Steel Flanges

- Oil and Gas Industry: Ideal for offshore rigs, subsea pipelines, and petrochemical refineries due to their resistance to saltwater and corrosive substances.

- Chemical Processing: Suitable for tanks, reactors, and piping systems handling aggressive chemicals, acids, and chlorides.

- Marine Engineering: Withstanding the corrosive effects of seawater, super duplex flanges are used in seawater cooling systems, desalination plants, and marine vessels.

- Pulp and Paper Industry: Resistant to acidic environments, making it suitable for pulp and paper processing equipment.

- Power Generation: Utilized in nuclear and conventional power plants where high strength and corrosion resistance are essential.

Manufacturing Standards for Super Duplex Stainless Steel Flanges

Our super duplex stainless steel flanges comply with international standards, ensuring top quality and performance:

- ASTM A182: Specification for forged or rolled alloy and stainless steel pipe flanges, forged fittings, and valves.

- ASME B16.5: Covers pipe flanges and flanged fittings for sizes up to 24 inches.

- ASME B16.47: Specification for large-diameter steel flanges (Series A and B).

- DIN EN 1092-1: European standard for steel flanges.

- ISO 15156/NACE MR0175: Specifies materials for sour gas environments in the oil and gas industry.

Flange Face Types

We offer super duplex stainless steel flanges in various face types for a range of sealing requirements:

- Flat Face (FF): Suitable for low-pressure applications with a smooth, flat surface.

- Raised Face (RF): Provides a secure seal in high-pressure systems.

- Ring Type Joint (RTJ): Features a grooved surface with a metal ring for sealing, perfect for high-pressure, high-temperature applications.

- Male-Female and Tongue-Groove: Adds sealing strength for applications requiring secure, leak-proof connections.

Surface Finishes and Coatings

Our super duplex stainless steel flanges are available with various finishes and coatings for enhanced durability and visual appeal:

- Pickled Finish: Removes impurities and provides a clean, corrosion-resistant surface.

- Polished Finish: Smooth, reflective finish ideal for aesthetic or sanitary applications.

- Sand Blasted: Non-reflective finish suitable for industrial use.

- Custom Coatings: Options like anti-rust paint or galvanizing are available for added protection.

Quality Assurance

Each super duplex stainless steel flange undergoes rigorous quality testing to ensure durability and reliability:

- Mechanical Testing: Tests for tensile strength, hardness, and impact resistance.

- Corrosion Testing: Ensures the flange’s resistance to pitting, crevice corrosion, and stress corrosion cracking.

- Dimensional Accuracy: Precision machining and finishing guarantee compatibility with a range of piping systems.

FAQs

Super duplex stainless steel offers higher corrosion resistance and strength due to its enhanced chromium, molybdenum, and nitrogen content, making it ideal for more aggressive environments.

Yes, super duplex stainless steel flanges can handle high temperatures; however, for extremely high-temperature applications, it’s recommended to verify suitability based on the specific environment and grade.

Why are super duplex flanges preferred in marine and offshore applications?

Products

Industry We Serve

- Oil & Gas industries

- Chemical process industries

- Pump and valve in high pressure component

- Food industries

- Pulp and paper industry

- Aerospace industry

- Power plant

- Mechanical component

- Sugar industry

- Cement industry