UNS S39274 is a highly alloyed super duplex stainless steel developed for maximum performance in corrosive and high-pressure environments. This grade is known for its excellent mechanical strength, high resistance to pitting and crevice corrosion, and impressive durability in aggressive media such as seawater and acidic chemicals. With a mixed microstructure of austenite and ferrite, UNS S39274 is particularly effective where conventional stainless steels fail.

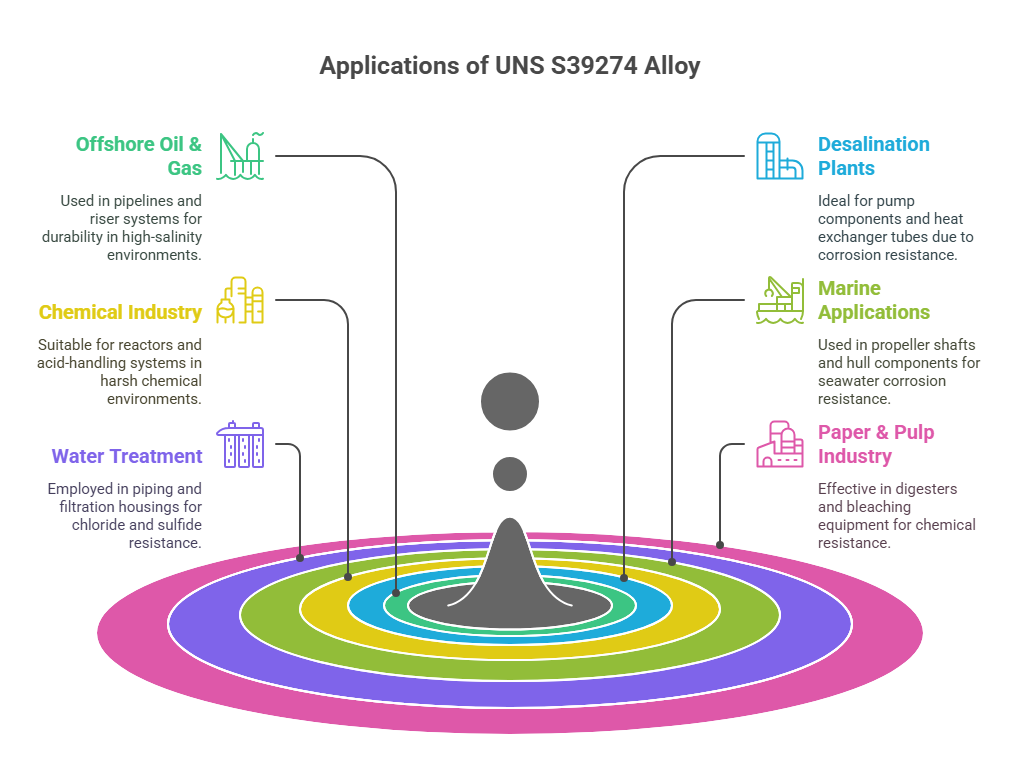

As industries evolve to meet more challenging operational demands, the use of super duplex stainless steel materials like UNS S39274 continues to grow. Below, we explore the most prominent industrial applications where this grade plays a vital role.

Why UNS S39274 is Chosen for Demanding Environments?

The superior performance of UNS S39274 lies in its chemical composition and duplex structure. It contains high levels of chromium (25–27%), molybdenum (3.5–4.5%), and nitrogen, which improve its pitting resistance equivalent number (PREN) to values above 40 — considered excellent for marine and chemical exposure.

Its high yield strength (550 MPa min) and tensile strength (750 MPa min) make it well-suited for load-bearing applications in harsh conditions.

1. Offshore Oil & Gas Platforms

UNS S39274 is widely used in the construction of offshore oil and gas infrastructure, including:

- Subsea pipelines

- Riser systems

- Manifolds and flanges

- Valve bodies and fittings

The alloy’s resistance to chloride-induced stress corrosion cracking ensures long-term durability in high-salinity environments.

2. Desalination Plants

Desalination facilities require materials that can endure continuous contact with seawater, brine, and cleaning chemicals. UNS S39274 is ideal for:

- High-pressure pump components

- Heat exchanger tubes

- Brine recirculation systems

Its ability to withstand erosion-corrosion, pitting, and crevice corrosion makes it the preferred choice in this industry.

3. Chemical and Petrochemical Industry

UNS S39274 resists a wide range of chemical substances, making it ideal for:

- Reactors and pressure vessels

- Acid-handling systems

- Storage tanks and piping

It performs exceptionally in acidic or chloride-rich process environments, where failure can result in costly shutdowns or hazards.

4. Marine and Shipbuilding Applications

Due to its corrosion resistance in seawater and marine atmosphere, UNS S39274 is used for:

- Propeller shafts

- Deck equipment

- Hull components and fasteners

It ensures longevity and strength in marine structural elements exposed to constant wet-dry cycling and saline air.

5. Water Treatment and Injection Systems

In both industrial water treatment and oilfield water injection applications, UNS S39274 is used in:

- High-pressure piping systems

- Pump bodies

- Filtration housings

Its resistance to corrosion from chlorides and sulfides ensures uninterrupted flow and reduced maintenance.

6. Paper & Pulp Industry

UNS S39274 is effective in digesters and bleaching equipment where exposure to acidic and oxidizing chemicals is common. Its ability to resist cracking and corrosion helps improve equipment lifespan.

Why Partnering with the Right Supplier Matters?

To realize the full performance of super duplex stainless steel, sourcing from experienced UNS S39274 suppliers is essential. Look for suppliers who offer:

- Complete mill test certifications

- Custom sizes and forging capabilities

- Quick delivery for global projects

- Adherence to ASTM A182 or ASTM A479 standards

Quality sourcing ensures the material behaves as expected in critical applications.

FAQs

UNS S39274 is used across offshore oil & gas, desalination, marine, chemical, and water treatment industries due to its strength and corrosion resistance.

Its high resistance to pitting and crevice corrosion in saline and brine environments makes it ideal for seawater applications.

Yes, with a yield strength above 550 MPa, it’s well-suited for high-pressure and structural applications.

It’s available as flanges, forged fittings, pipes, bars, and custom-machined components certified to ASTM or EN standards.