ASTM A182 UNS S39274 is a widely recognized specification for forged or rolled alloy and stainless steel pipe flanges, forged fittings, and valves used in high-temperature service. Within this standard, UNS S39274 represents a super duplex stainless steel grade known for its high mechanical strength, excellent corrosion resistance, and suitability for extreme industrial conditions. This material has become a trusted choice in sectors like oil & gas, petrochemicals, desalination, and marine operations.

This guide breaks down the key properties, benefits, and industrial relevance of ASTM A182 UNS S39274 to help engineers and buyers make informed material decisions.

Understanding ASTM A182 Standard

The ASTM A182 standard issued by ASTM International covers forged or rolled alloy and stainless steel components used in pressure systems and high-temperature applications. These include:

- Flanges

- Valves

- Fittings

- Other pressure-containing parts

ASTM A182 ensures the material’s strength, durability, and resistance under pressure, making it essential for systems where failure is not an option.

What is UNS S39274?

UNS S39274 is a grade of super duplex stainless steel characterized by a dual-phase microstructure of austenite and ferrite. Its alloying composition includes high levels of chromium, molybdenum, and nitrogen, which improve resistance to pitting, crevice corrosion, and stress corrosion cracking.

Commonly associated with super duplex stainless steel, UNS S39274 is designed for superior performance in highly corrosive environments such as offshore oil rigs and seawater systems.

What is UNS S39274?

| Element | Percentage (%) |

|---|---|

| Chromium | 25.0 – 27.0 |

| Nickel | 6.0 – 8.0 |

| Molybdenum | 3.5 – 4.5 |

| Nitrogen | 0.3 max |

| Carbon | 0.03 max |

| Manganese | 1.0 max |

| Silicon | 0.8 max |

| Iron | Balance |

This composition gives the material a PREN (Pitting Resistance Equivalent Number) above 40, which is considered highly resistant to localized corrosion in chloride environments.

Key Features of ASTM A182 UNS S39274 Material

- High Strength: Almost twice the strength of austenitic stainless steel.

- Corrosion Resistance: Excellent protection against chlorides, sulfides, and aggressive chemicals

- Stress Corrosion Cracking Resistance: Particularly effective in sour service environments

- Extended Service Life: Designed for performance in high-pressure and high-temperature applications

- Versatility: Available in forged flanges, fittings, valves, and custom shapes

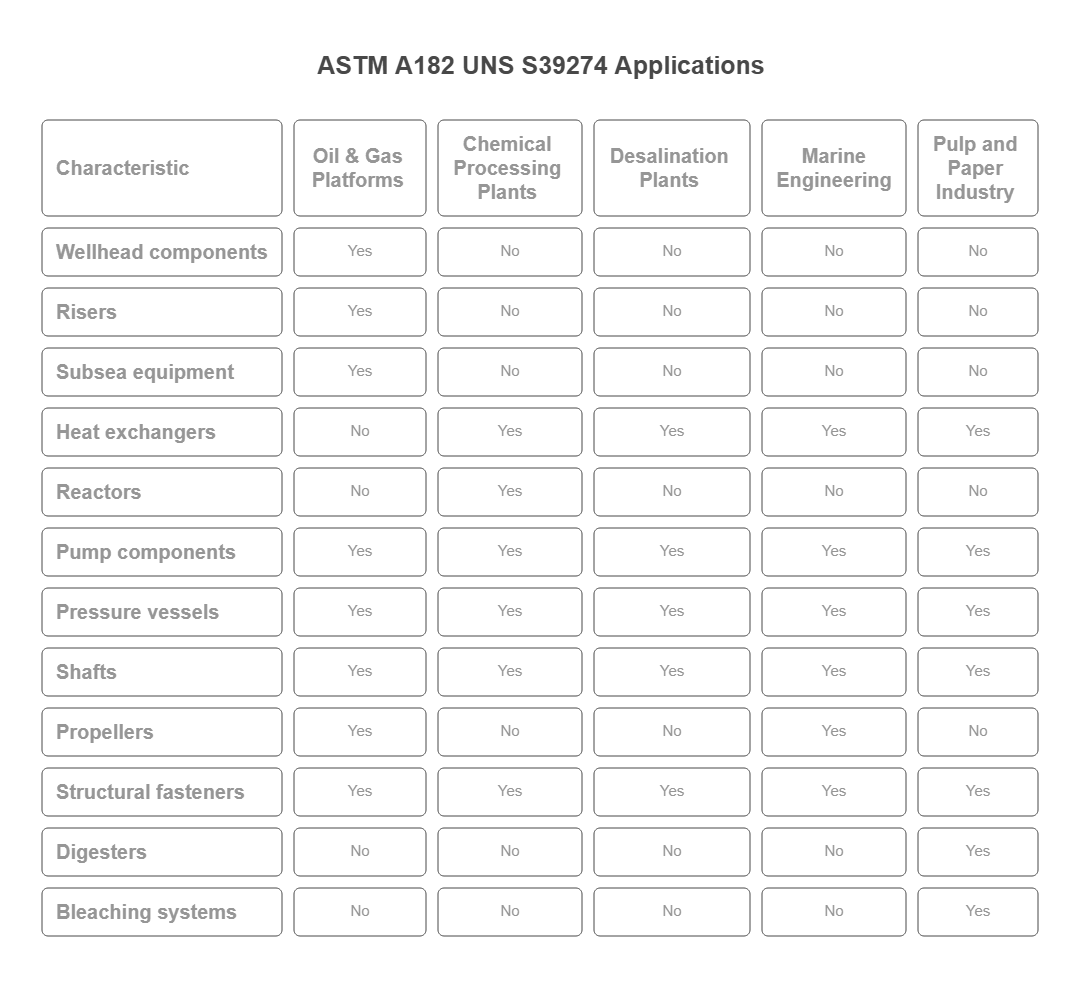

Typical Applications in Industry

Due to its unique blend of strength and corrosion resistance, ASTM A182 UNS S39274 material is used across several demanding sectors:

- Oil & Gas Platforms: Wellhead components, risers, and subsea equipment

- Chemical Processing Plants: Heat exchangers and reactors

- Desalination Plants: Pump components and pressure vessels

- Marine Engineering: Shafts, propellers, and structural fasteners

- Pulp and Paper Industry: Digesters and bleaching systems

Why Choose ASTM A182 Material in Super Duplex Grade?

- Biocompatibility: Accepted by human tissue with minimal reactions.

- Precision Machinability: Ideal for complex and delicate part production.

- Fatigue Resistance: Performs well under stress and load cycles.

FAQs

This material is primarily used in high-temperature, high-pressure applications like flanges, fittings, and valves for offshore, chemical, and marine industries.

Yes, it falls under the category of super duplex stainless steels due to its high chromium and molybdenum content and its superior corrosion resistance.

ASTM A182 defines strict mechanical, chemical, and dimensional requirements to guarantee performance in pressure-containing parts.

Welding is possible but requires expertise and preheat/post-weld practices to maintain the correct phase balance and avoid cracking.