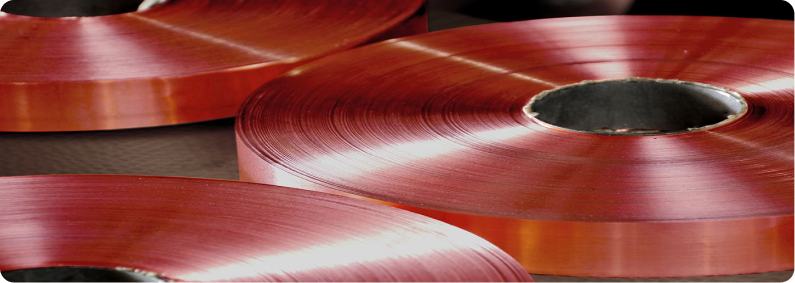

Copper C10100 (Oxygen-Free Copper), C11000 (Electrolytic Tough Pitch Copper)

Copper C10100 and C11000 are recognized as two popular grades of copper. They are renowned for their outstanding electrical and thermal conductivity, corrosion resistance, and multifunctional characteristics. These grades are well–suited for electrical, industrial, and decorative uses because of their advantageous characteristics of conductivity and corrosion resistance, which optimize their performance and reliability.

Copper C10100 and C11000 Features:

C10100 (Oxygen-free copper): –

- High Purity: Copper C10100 is 99.99% pure copper, the remaining material is oxygen, enabling an unmatched conductivity and corrosion resistance.

- Exceptional Conductivity: Copper C10100 has the highest electrical and thermal conductivity of all copper grades; therefore, it is a popular choice for applications that require sensitive electronics or electrical connections.

- Ductile and Workable: Copper C10100 can be easily formed and fabricated into all types of shapes and forms for industrial or decorative applications.

C11000 (Electrolytic tough pitch copper): –

- Versatile Conductivity: C11000 has a conductivity slightly less than C10100 but excellent for general electrical applications.

- Cost-Effective Alternative: C11000 combines excellent performance and value when selected over C10100 and is the more common choice of the two grades.

- Corrosion Resistance: C11000 resists surface corrosion in environments where moisture or mildly corrosive factors are present.

Applications of Copper C10100 and C11000

C10100 (Oxygen-Free Copper):

- Electronics and Semiconductors: Ideal for wiring, circuit boards, and connectors requiring superior conductivity.

- Vacuum and High-Frequency Applications: Optimal for devices that must operate with minimal outgassing, such as vacuum tubes and high-frequency cables.

- Medical and Scientific Equipment: Often used in laboratory and medical equipment since it meets high purity standards and offers suitable conductivity.

C11000 (Electrolytic Tough Pitch Copper):

- Electrical Wiring and Busbars: Common in power distribution systems, in switchgear, and power transformers.

- Industrial Components: Found in plumbing components, industrial machinery, and heat transfer equipment.

- Construction and Architecture: Used in roofing, cladding, and for decorative applications due to its attractive aesthetic and corrosion resistance.

Advantages of Copper C10100 and C11000

- High Electrical and Thermal Conductivity: C10100 and C11000 are ideal for applications requiring electrical and thermal conductivity, providing minimal loss of energy.

- Excellent Corrosion Resistance: C10100 and C11000 can be used for indoor or outdoor applications where rust and oxidation resistance is required.

- Ease of Fabrication: C10100 and C11000 are both extremely ductile and malleable, allowing the material to be fabricated easily.

- Sustainable and Recyclable: C10100 and C11000 can be recycled (100%), and because the recycling process does not degrade the performance characteristics, it is an eco-friendly choice for manufacturers.

C10100 and C11000 Standards:

C10100 (Oxygen-Free Copper):

ASTM B152 (Plates, Sheets, and Strips)

ASTM B187 (Rods, Bars, and Shapes)

C11000 (Electrolytic Tough Pitch Copper):

ASTM B152 (Plates, Sheets, and Strips)

ASTM B187 (Rods, Bars, and Shapes)

ASTM B88 (Plumbing Tubes)

Why Use C10100 and C11000 Copper?

- Industry-Leading Performance: Both grades provide unparalleled conductivity and corrosion resistance.

- Wide Range of Applications: Suitable for a wide range of applications, from those in electronics to industrial applications.

- Sustainability: Both are 100% recyclable materials, in a use to build greener.

- Custom Options: Available in many shapes, sizes, and finishes to fit your project’s needs.

FAQs

Yes, C10100‘s oxygen free properties restrict gas emissions, therefore are very usable in a vacuum.

Yes, C11000 does provide decent corrosion resistance and can be used outdoors for roofing, cladding, and plumbing.

Choose C10100 when high purity with high conductivity are required (like electronics), and choose C11000, (Electrolytic Tough Pitch Copper), when a lower cost metal is required for industrial use, as well as being more general use – (i.e. electrical).

Products

Industry We Serve

- Oil & Gas industries

- Chemical process industries

- Pump and valve in high pressure component

- Food industries

- Pulp and paper industry

- Aerospace industry

- Power plant

- Mechanical component

- Sugar industry

- Cement industry