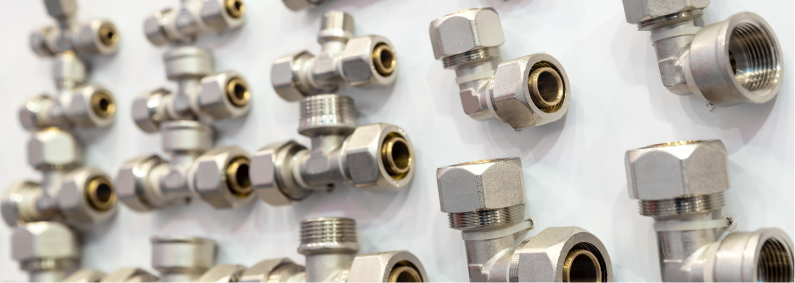

Forged Fittings

Riyaarth Overseas is a renowned manufacturer and exporter of forged fittings, providing reliable piping solutions for various industries worldwide. Our forged fittings comply with international standards such as ASME, ANSI, and DIN, ensuring durability, precision, and strength for high-pressure and high-temperature applications. We cater to industries such as oil and gas, petrochemicals, power generation, and many more.

Forged fittings are critical components in high-pressure piping systems, offering a secure and leak-proof connection. These fittings are manufactured by forging processes, resulting in enhanced strength and durability compared to cast fittings. Forged fittings are available in threaded or socket weld configurations, providing flexibility for different applications.

Types of Forged Fittings

- Elbows (90°, 45°): Used to change the direction of fluid flow in a piping system.

- Tees (Equal and Reducing): Designed to combine or split fluid flow in pipelines.

- Couplings (Full and Half): Connect two pipes in a straight line.

- Unions: Allow easy disassembly and reassembly of piping systems.

- Caps: Used to close the end of a pipe, preventing fluid flow.

- Plugs: Threaded fittings are used to close the end of a pipe.

- Bushings: Reduces the size of a threaded pipe connection.

- Crosses: Provides four-way connections in piping systems.

Advantages of Forged Fittings:

- High Strength and Durability: Forging improves the structural integrity of the fittings, making them suitable for high-pressure environments.

- Corrosion Resistance: Made from high-quality materials that resist corrosion, ensuring a longer service life.

- Leak-Proof: Precise manufacturing ensures a tight seal, reducing the risk of leakage in critical applications.

- Cost-Effective: Their long service life and reduced need for maintenance make forged fittings a cost-effective solution.

Specifications and Features

- Size Range: 1/8” (DN6) to 4” (DN100).

- Standards: Conforms to ASME B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, MSS-SP-97, BS 3799, and other international standards.

- Pressure Ratings: Class 2000, Class 3000, Class 6000, and Class 9000.

- Materials:

- Carbon Steel: ASTM A105, A350 LF2.

- Stainless Steel: ASTM A182 F304, F304L, F316, F316L, F321, F347, F904L.

- Alloy Steel: ASTM A182 F1, F5, F9, F11, F22, F91.

- Special Alloys: Duplex, Super Duplex, Nickel Alloys (Inconel, Monel, Hastelloy, etc.).

Types of End Connections

- Threaded (NPT/BSPT/BSP): Threaded fittings are used in systems where welding is impractical or where quick assembly and disassembly are required.

- Socket Weld: These fittings are welded to the pipe, offering a strong and durable connection for high-pressure applications.

Applications of Forged Fittings

Forged fittings are ideal for industries that demand high-performance piping systems under severe pressure and temperature conditions:

- Oil and Gas

- Petrochemical

- Power Generation

- Water Treatment

- Pharmaceutical

- Food and Beverage

- Construction and Infrastructure

Value-Added Services

- CNC Machining: Ensures precision cutting and finishing for custom-made fittings.

- Heat Treatment: For added durability and strength.

- Surface Treatments: Including pickling, passivation, sandblasting, and electro-polishing for enhanced corrosion resistance.

- Customization: We offer tailor-made forged fittings in various sizes, materials, and configurations to meet specific project requirements.

Marking and Packaging

- Marking: Each fitting is marked with material grade, size, pressure rating, and heat number for full traceability.

- Packaging: Our fittings are securely packed in wooden crates or pallets to ensure safe and damage-free delivery to international destinations.

Quality Assurance

Riyaarth Overseas is committed to delivering the highest quality forged fittings. Each product undergoes rigorous testing and inspection to meet international quality standards, ensuring strength, reliability, and dimensional accuracy.

- Testing: Hydrostatic testing, radiography, ultrasonic testing, and material composition analysis are conducted as part of our quality control process.

- Certifications: We provide EN 10204 3.1B Manufacturer Test Certificates, 100% Radiography Test Reports, Raw Materials Certificates, and Third-Party Inspection Reports to ensure product compliance and customer satisfaction.

Global Export Network

Riyaarth Overseas supplies forged fittings to industries across the globe, including regions like the United States, Europe, Russia, the Middle East, and Southeast Asia. Our reputation for quality and reliability has earned us a strong client base in industries like petrochemicals, power generation, pharmaceuticals, and more.

For premium forged fittings that meet the most demanding requirements, contact Riyaarth Overseas today. Our expert team is ready to help you find the right solution for your industrial piping systems.

FAQ's

Forged fittings are stronger and more durable than cast fittings due to the forging process, making them ideal for high-pressure and high-temperature applications.

Threaded fittings are typically used in low-pressure systems or in applications where pipes may need to be frequently disassembled, while socket weld fittings are used in high-pressure systems requiring a stronger, more permanent connection.

Yes, we offer customized forged fittings based on your specific requirements, including special materials, sizes, and end connections.

Products

Industry We Serve

- Oil & Gas industries

- Chemical process industries

- Pump and valve in high pressure component

- Food industries

- Pulp and paper industry

- Aerospace industry

- Power plant

- Mechanical component

- Sugar industry

- Cement industry