Introduction

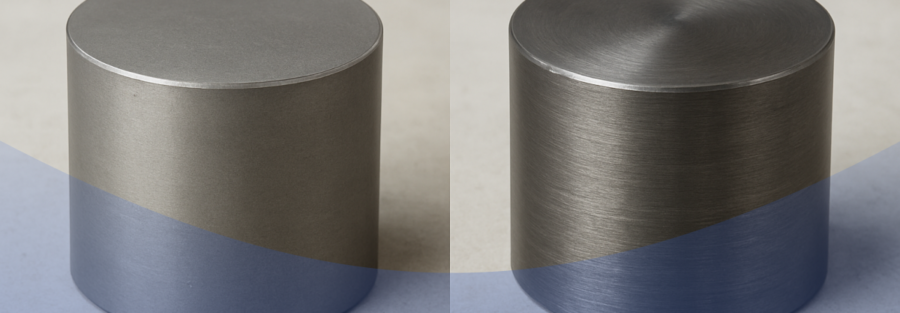

Titanium material is known for being lightweight, strong, and highly resistant to corrosion. Steel, on the other hand, is a widely used metal known for its strength, durability, and cost-effectiveness. But when industries compare titanium vs steel, they often want to know one thing: Which material performs better for demanding applications?

In this blog, we will compare titanium material and steel in simple language. We’ll explain their properties, advantages, uses, and differences so buyers and engineers can make the right choice.

Table of Contents

- What Is Titanium Material?

- What Are Titanium’s Main Properties?

- What Are Titanium Alloys?

- What Is Steel and How Does It Compare?

- Titanium vs Steel: Key Differences

- Applications of Titanium Alloys

- Which Material Should You Choose?

- FAQs

1. What Is Titanium Material?

Titanium is a chemical element known for its high strength, low weight, and excellent corrosion resistance. Because of its unique balance of strength and lightness, titanium is often used in aerospace, medical, marine, and chemical industries.

In simple words:

Titanium is strong like steel but much lighter and better at resisting corrosion.

2. What Are Titanium’s Main Properties?

Here are the most important titanium properties:

- High Strength: Titanium is as strong as steel.

- Lightweight: Titanium is about 45% lighter than steel.

- Corrosion Resistant: Works well in seawater, chemicals, and extreme conditions.

- High Temperature Resistance: Titanium alloys keep their strength at high heat.

- Non-Toxic and Biocompatible: Safe for medical use.

- Long Lifespan: Very durable and requires low maintenance.

These properties make titanium material ideal for industries where both strength and weight matter.

3. What Are Titanium Alloys?

Pure titanium is strong, but when combined with elements like aluminum, vanadium, or molybdenum, it forms titanium alloys. These alloys offer even greater strength, heat resistance, and durability.

Examples include:

- Grade 5 Titanium (Ti-6Al-4V): A superior titanium alloy with outstanding performance.

- Grade 2 Titanium: Known for excellent corrosion resistance.

- Grade 9 Titanium: Lightweight and used in aerospace tubes.

Titanium alloys are trusted in advanced engineering, including aircraft, rockets, and medical implants.

4. What Is Steel and How Does It Compare?

Steel is an iron-carbon alloy used almost everywhere—from construction and cars to household appliances. Steel is strong, affordable, and easy to manufacture.

But steel has some limitations:

- It is heavier than titanium.

- It can rust if not treated or alloyed properly.

- It loses strength faster than titanium at high temperatures.

5. Titanium vs Steel: Key Differences

| Feature | Titanium Material | Steel |

| Weight | Much lighter | Heavy |

| Strength | Very strong, even at high temperatures | Strong, but weakens at high heat |

| Corrosion Resistance | Excellent | Moderate, depending on grade |

| Cost | Higher | More affordable |

| Lifespan | Very long | Depends on the environment |

| Best Use | Aerospace, medical, marine, chemical | Construction, machinery, automotive |

Simple Explanation:

Choose titanium when performance matters. Choose steel when cost matters.

6. Applications of Titanium Alloys

Titanium alloy applications cover many industries due to their ability to handle stress, heat, and corrosion.

Top Uses Include:

- Aerospace: Aircraft parts, landing gear, engine components.

- Medical: Implants, surgical tools.

- Marine: Ship parts, offshore equipment.

- Chemical Processing: Pipes, heat exchangers, pressure vessels.

- Automotive & Motorsports: High-performance components.

- Power Generation: Turbine blades, condenser tubes.

Industries choose titanium alloys when they need lightweight strength and long-term reliability.

7. Which Material Should You Choose?

Choose Titanium Material if you need:

- High corrosion resistance

- Lightweight strength

- High temperature performance

- Long-lasting durability

- Safe and non-toxic materials

Choose Steel if you need:

- Lower cost

- Strong structural support

- Easy fabrication

- General-purpose use

If your project involves chemicals, seawater, medical components, aerospace parts, or high temperatures, titanium is the better choice.

Titanium material is a high-performance metal that offers excellent strength, low weight, and outstanding corrosion resistance. While steel remains an affordable and widely used option, titanium is the preferred choice for industries that require premium performance, durability, and resistance to extreme environments.

At Riyaarth Overseas, we supply high-quality titanium material, titanium alloys, pipes, bars, and custom components for industrial buyers worldwide. Contact us today to choose the best titanium grade for your project

8. FAQs

Q1. Is titanium stronger than steel?

Titanium material is not always stronger, but its strength-to-weight ratio is much better than steel.

Q2. Why is titanium more expensive?

Titanium is harder to extract and process, which increases its cost. However, it lasts longer, reducing lifetime costs.

Q3. Is titanium good for industrial buyers?

Yes. Industries choose titanium for high performance, especially in aerospace, marine, medical, and chemical systems.

Q4. Are titanium alloys better than pure titanium?

Yes. Titanium alloys provide more strength and heat resistance.