Lap Joint Flanges

Riyaarth Overseas is a leading manufacturer and exporter of high-quality ASME/ANSI/DIN standard lap joint (LJ) flanges. We specialize in providing rapid delivery programs for carbon steel, stainless steel, nickel alloy, and alloy steel lap joint flanges. Our lap joint flanges are widely used in various industrial applications and are designed to meet stringent international standards.

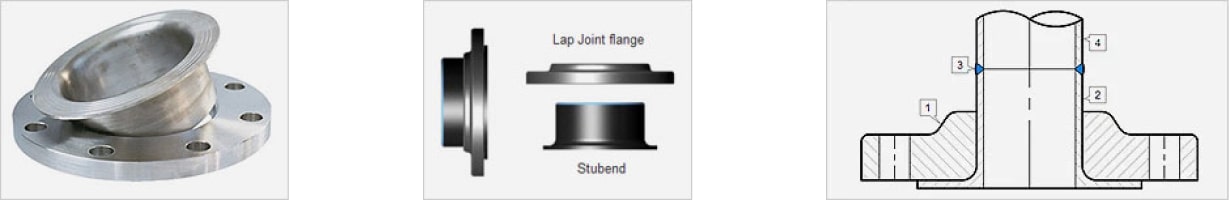

Lap joint flanges are similar to other industrial flanges, but they are primarily used in conjunction with a “Lap Joint Stub End.” These flanges are perfect for applications where frequent dismantling for inspection and cleaning is required. Since the lap joint flange slips over the pipe, it is not welded or secured directly to it. Instead, the flange’s pressure is transferred to the gasket by the flange pressing against the back of the pipe lap (Stub End).

Key Benefits of Lap Joint Flanges:

- Swiveling Ability: Facilitates alignment of opposing flange bolt holes.

- Cost-Effective: Inexpensive carbon steel flanges can be used with corrosion-resistant pipes, reducing material costs.

- Reusability: Flanges can be salvaged for reuse in systems prone to erosion or corrosion.

Specifications and Features

- Size Range: From 1/2″ (15 NB) to 48″ (1200NB), covering a wide range of pipeline sizes.

- Standards: Complies with ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA. We also offer custom drawings to meet specific project requirements.

- Pressure Ratings: Class 150 to Class 2500, and PN6 to PN64, catering to various operating pressures.

- Materials:

- Carbon Steel: ASTM A105/A105N, A350 LF1, LF2, LF3, A694 F42 to F70.

- Stainless Steel: ASTM A182 F304/304L, F316/316L, F310, F321, F904L.

- Alloy Steel: ASTM A182 F1, F5, F9, F11, F22, F91.

- Special Alloys: Including Duplex, Super Duplex, and Nickel Alloys for demanding environments.

Flange Face Types

Available in Flat Face (FF), Raised Face (RF), and Ring Type Joint (RTJ) configurations, depending on the application and sealing requirements.

Coating and Surface Treatment

Options include anti-rust paint, oil black paint, yellow transparent, zinc plating, and cold and hot dip galvanizing to enhance corrosion resistance and longevity.

Value-Added Services

- CNC Machining: Ensures precision and accuracy for custom orders.

- Customization: Flanges can be customized to meet the exact specifications of your project.

Applications

Lap joint flanges are commonly used in industries that require frequent maintenance and inspection, including:

- Shipbuilding

- Power Generation

- Petrochemical Plants

- Oil Refineries

- Wastewater Treatment Plants

- Paper Mills

- Pharmaceutical Plants

Global Reach

Our lap joint flanges are exported to various regions, including the United States, Europe, Russia, Turkey, the UAE, Saudi Arabia, Brazil, Mexico, and many others, reflecting our commitment to serving a global market.

Marking and Packaging

- Marking: All products are marked with grade, size, lot number, and other necessary details for traceability.

- Packaging: Products are securely packaged in wooden cases to prevent damage during transit. Special marking and custom packaging are available upon request.

Quality Assurance

At Riyaarth Overseas, quality is our top priority. Every flange is subjected to rigorous inspection at each stage of production to ensure compliance with international standards. We adhere to ASTM, ASME, MSS, DIN, EN, and JIS codes, ensuring superior quality.

- Test Certificates: EN 10204 3.1B Manufacturer Test Certificate, Raw Materials Certificate, 100% Radiography Test Report, and Third-Party Inspection Reports are provided as required.

Contact Us

For high-quality lap joint flanges that meet your project needs, contact Riyaarth Overseas today. Our experts are ready to help you select the perfect solution for your application.

FAQ's

Lap joint flanges provide flexibility by allowing the flange to rotate around the pipe for easy alignment, and they are ideal for systems requiring frequent dismantling.

While lap joint flanges are typically used in lower-pressure applications due to their lower weight-holding capacity, they are excellent for systems requiring regular maintenance or inspection.

The lap joint flange is used in conjunction with a stub end. The flange itself is not welded to the pipe; instead, it slides over the pipe and is bolted in place with the help of the stub end, transferring pressure to the gasket.

Products

Industry We Serve

- Oil & Gas industries

- Chemical process industries

- Pump and valve in high pressure component

- Food industries

- Pulp and paper industry

- Aerospace industry

- Power plant

- Mechanical component

- Sugar industry

- Cement industry