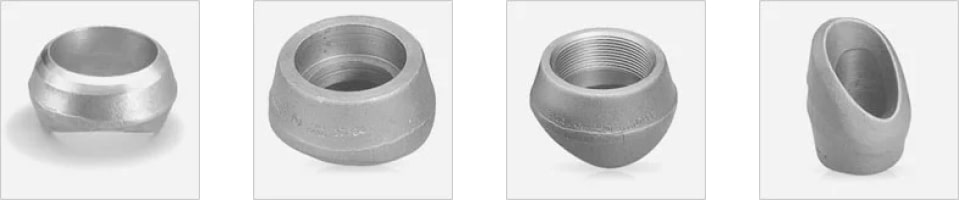

Pipe Outlet Fittings

Riyaarth Overseas is a prominent manufacturer, exporter, and supplier of high-quality Pipe outlet fittings, including welding, socket weld, and threaded outlets. Our fittings are manufactured by international standards such as MSS-SP-97, and ASME B16.11, and are available in classes 3000, 6000, and 9000. We provide a diverse range of material grades including ASTM A105 for carbon steel and ASTM A182 for stainless steel, catering to various industrial requirements.

Product Range

Our extensive line of forged Pipe outlet fittings includes:

- Welding Outlets

- Socket Weld Outlets

- Threaded Outlets

- Lateral and Elbow Outlets

- Nipple Outlets

These products are available in a variety of materials to suit different applications:

- Stainless Steel: Grades 304, 304L, 316, 316L, 317L, 321, 347, and 904L.

- Carbon Steel: ASTM A105, catering to general industrial needs.

- Alloy Steel: Grades including F1, F5, F9, F11, F22, and F91.

- Duplex and Super Duplex Steel: For enhanced strength and corrosion resistance.

- Low Temperature Carbon Steel: A350 LF2 and LF3 for cold environments.

- Nickel Alloys: Including Monel, Inconel, Hastelloy, and Nickel 200/201 for high corrosion resistance.

- Copper Alloys: Cupro Nickel 90/10 and 70/30 for marine and offshore applications.

Applications

Pipe outlet fittings are extensively used across:

- Oil Refineries

- Petrochemical Plants

- Power Generation

- Pulp and Paper Processing

- Chemical Processing Plants

These fittings are crucial for applications involving sulphuric, phosphoric, and acetic acids, as well as environments requiring high mechanical strength and corrosion resistance.

Quality and Compliance

- Standards: Our fittings meet ASTM, ASME, MSS, DIN, EN, and JIS standards.

- Quality Assurance: Each fitting undergoes rigorous inspection at each stage of production, ensuring the highest quality standards. We offer EN 10204 3.1B Test Certificates, 100% Radiography Test Reports, and Third Party Inspection Certificates.

- Customizations: We can manufacture fittings in special materials and custom sizes to meet specific project requirements.

Marking & Packing

Each fitting is marked with the material grade, size, class, and heat number. Standard export packaging in wooden cases ensures that fittings reach our clients without any damage. Custom marking is available upon request.

Choose Riyaarth Overseas for reliable and durable Pipe outlet fittings designed to meet your specific needs. Contact us today to discuss your requirements and discover how our top-quality fittings can contribute to the success of your projects.

FAQ's

- Welding Outlets: These are directly welded onto the pipe, providing a strong, permanent leak-proof connection. Ideal for high-pressure applications.

- Socket Weld Outlets: Involves a pipe being inserted into a recessed area of the fitting. Useful for smaller pipe diameters and where leakage integrity is important, but not as permanent as welded connections.

- Threaded Outlets: These fittings are screwed onto the pipe using threaded connections. They are easier to install and remove and suitable for low to medium-pressure applications.

Yes, pipe outlet fittings are suitable for high-temperature applications when made from appropriate materials such as high-grade stainless steel or nickel alloys. These materials maintain structural integrity and resist corrosion even under high thermal stress.

The choice of material depends on the specific conditions of your application, including the type of fluids being transported, operating temperature, pressure, and environmental conditions. For corrosive environments, stainless steel or nickel alloys are preferred for their corrosion resistance. For high-pressure and high-temperature applications, alloy steels might be more appropriate. Consulting with the manufacturer can provide guidance based on the specific requirements of your system.

Products

Industry We Serve

- Oil & Gas industries

- Chemical process industries

- Pump and valve in high pressure component

- Food industries

- Pulp and paper industry

- Aerospace industry

- Power plant

- Mechanical component

- Sugar industry

- Cement industry