In industrial piping systems, achieving seamless flow transition between pipes of different diameters is critical. This is where a pipe reducer plays a key role. Whether you’re dealing with water lines, chemical systems, or HVAC piping, using the right reducer for pipe ensures efficient flow control and minimizes turbulence.

This in-depth guide covers everything about types of reducers, their dimensions, functionality, and why selecting the right reducer pipe type is essential for reliable industrial plumbing.

What Is a Pipe Reducer?

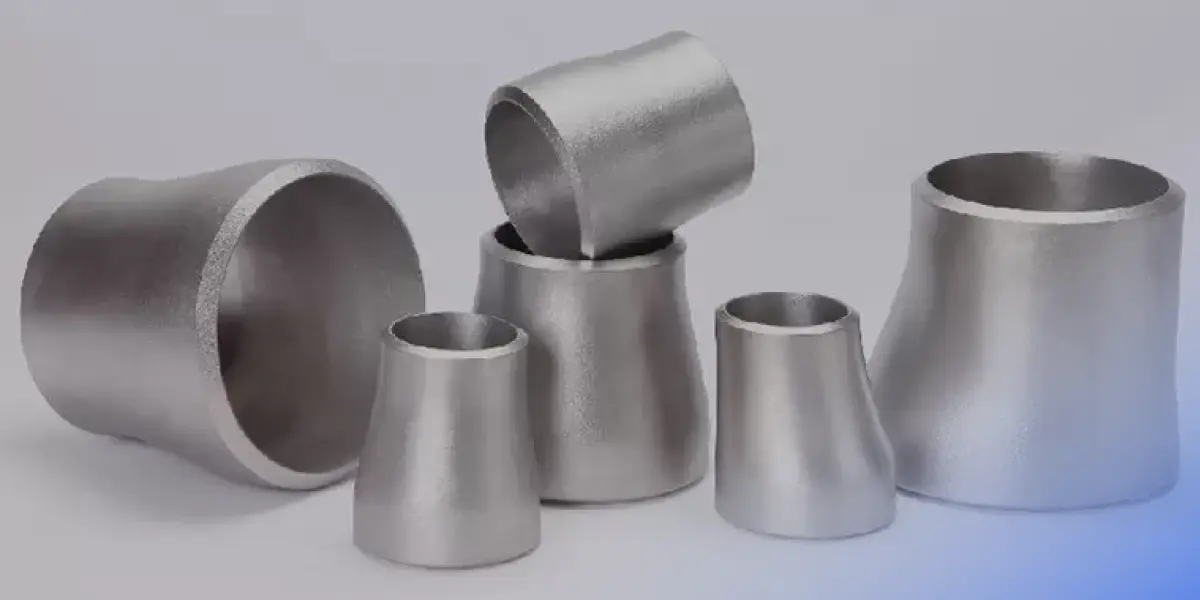

A pipe reducer is a type of pipe fitting used to connect two pipes of different diameters. It reduces or increases the pipe size to meet flow requirements or to adapt to existing piping. It’s an essential component in plumbing, oil & gas, chemical, and process industries.

Common Designations:

There are two main types of reducer fittings used in piping:

- Concentric Reducer

- Eccentric Reducer

- Concentric Reducer

Let’s explore their differences in design and application.

Types of Pipe Reducers Explained

| Reducer Type | Shape & Centerline | Applications |

| Concentric Reducer | Cone-shaped, the centerlines of both ends remain aligned | Vertical piping, pump discharge, fluid systems |

| Eccentric Reducer | Flat on one side, off-centered ends | Horizontal piping, to prevent air accumulation |

| Threaded Reducer | Has threads for easy screw-in pipe connection | Low-pressure systems and domestic plumbing |

| Butt-Weld Reducer | Welded to pipes, offers a strong and leak-proof connection | High-pressure and temperature piping systems |

| Socket Weld Reducer | Fits into pipe sockets, then welded | Small-diameter, high-pressure lines |

Each type of reducer in piping has a specific role depending on alignment needs, flow behavior, and pressure conditions.

Concentric vs Eccentric Reducer – What’s the Difference?

Concentric Reducer (Reducer Pipe Concentric)

- Cone-shaped fitting.

- Used when maintaining the centerline elevation is important.

- Commonly used in pump discharge lines or vertical pipelines.

Eccentric Reducer

- One side is flat, and the other side is angled.

- Prevents air pockets in horizontal flow.

- Ideal for suction lines, especially near pumps, to avoid cavitation.

Where Is Super Duplex Stainless Steel Used?

Feature | Concentric Reducer | Eccentric Reducer |

Centerline | Same | Offset |

Used in | Vertical lines | Horizontal lines |

Prevents Air Accumulation | No | Yes |

Best For | Liquid flow applications | Suction side of pump systems |

Standard Reducer Pipe Dimensions

Nominal Size (Inches) | Large End (mm) | Small End (mm) | Length (mm) |

2” x 1” | 60.3 | 33.4 | 76 |

4” x 2” | 114.3 | 60.3 | 102 |

6” x 4” | 168.3 | 114.3 | 127 |

8” x 6” | 219.1 | 168.3 | 152 |

10” x 8” | 273.0 | 219.1 | 178 |

Note: These are standard dimensions. Always refer to ASME B16.9 or the manufacturer specifications for accurate sizing.

Materials and Standards for Pipe Reducers

- Carbon Steel

- Stainless Steel

- Alloy Steel

- PVC or Plastic

- Copper or Brass

Common Manufacturing Standards:

- ASME B16.9 – Butt-welded reducers

- ANSI B16.11 – Forged socket weld/threaded reducers

- ASTM A234 – Steel pipe fittings

These industry standards ensure compatibility, pressure resistance, and long-term durability for plumbing systems.

Where Are Pipe Reducers Used?

Industry | Application |

Oil & Gas | Downstream pipelines, flow control |

HVAC Systems | Air conditioning duct transitions |

Chemical Plants | Acid or alkali pipelines |

Food Processing | Sanitary stainless steel reducers |

Plumbing | Domestic water supply networks |

In industrial piping, the selection of plumbing reducers must consider flow rate, media type, pressure rating, and alignment requirements for reliable connections.

How Does a Pipe Reducer Work?

A pipe reducer works by gradually changing the diameter of the pipe to reduce the flow area. This:

- Minimizes flow turbulence.

- Prevents cavitation in pump suction lines.

- Maintains laminar flow and efficient pressure handling.

In a reducer in plumbing, this transition is crucial in preventing pipe damage due to abrupt changes in fluid velocity or pressure.

Summary Table – Reducer Types at a Glance

Reducer Type | Best Used In | Key Advantage |

Concentric | Vertical piping | Centerline alignment |

Eccentric | Horizontal piping | Air pocket prevention |

Butt-Weld | High-pressure systems | Seamless and leak-proof |

Threaded | Low-pressure, temporary connections | Easy installation |

Socket Weld | Small pipe diameters | Secure joint for pressure |

Look for pipe reducer manufacturers in India with global quality standards and prompt delivery.

Final Thoughts

Choosing the right reducer for pipe is more than just a sizing decision—it’s about optimizing fluid dynamics, reducing stress on components, and ensuring system safety. With several types of reducer for pipe available, understanding their design, purpose, and dimension standards helps avoid costly errors in industrial systems.

Partner with a trusted supplier to get reducers that are easy to install, compliant with global standards, and built to withstand demanding environments.

FAQs

A pipe reducer, such as stainless steel or brass reducers, connects pipes of different diameters, ensuring reliable connections and maintaining consistent flow.

An eccentric reducer is preferred in plumbing systems because it prevents air accumulation and ensures smooth pump operation.

The main types of plumbing reducers include concentric, eccentric, butt-weld, threaded, and socket-weld reducers.

Yes, plumbing reducers help adapt water lines of varying diameters, ensuring reliable connections in residential and industrial plumbing systems.

Consider flow rate, pressure, pipe material, and system alignment when selecting plumbing reducers. Refer to ASME B16.9 or manufacturer charts for exact sizing.