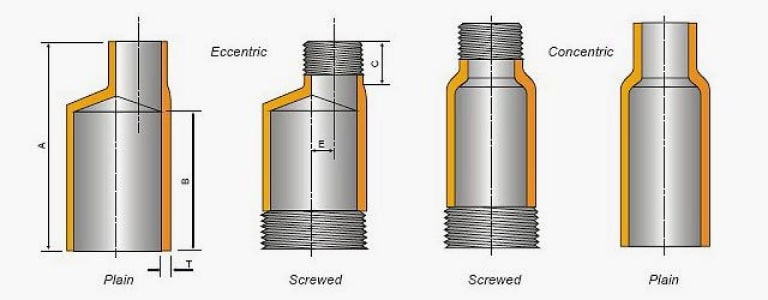

Swage Nipple/Pipe Swage

Riyaarth Overseas is renowned for its high-quality stainless steel, carbon steel, and alloy steel swage nipples. As a leading manufacturer and supplier, our products adhere to the stringent standards of MSS-SP-95, ASME B16.11, and BS 3799. Our commitment to quality ensures that our swage nipples meet the exact requirements of diverse industries across the globe.

Comprehensive Product Range

We specialize in both concentric and eccentric swage nipples, available in a variety of sizes from 1/8” to 8” (DN8 to DN200). Our products are crafted from superior raw materials such as:

- A106 Gr. B Seamless Pipes

- A105/A105N Bars

- ASTM A182 304/304L and 316/316L Bars

- Duplex and other high-grade alloy seamless pipes

Specifications and Customization

- End Connections: Available with Plain Both Ends (PBE), Bevel Both Ends (BBE), and Thread Both Ends (TBE), among other customized end types.

- Thicknesses: Standard, Extra Heavy, Schedule 160, and Double Extra Heavy, catering to various pressure requirements.

Material Finish: Options include Electro-Galvanized Coating, Blackodising Finish, Sand Blasting, and Pickled Finish for enhanced corrosion resistance and durability.

Global Distribution

Our swage nipples are distributed across major industrial hubs in India and exported to countries including Brazil, UAE, Italy, United States, and many others, reflecting our global reach and reliability.

Quality and Compliance

- Certifications: EN 10204 3.1, along with Raw Material Certificates and comprehensive NDT Reports from NABL-approved labs.

- Inspection: Each piece undergoes a rigorous inspection process, ensuring compliance with ASTM, ASME, MSS, DIN, EN, and JIS standards. We also offer third-party inspection services as per customer requests.

Marking and Packaging

Each swage nipple is meticulously marked with its grade, size, lot number, and heat code to ensure traceability. Standard export packaging in wooden cases guarantees that our products arrive in pristine condition, ready for deployment.

Applications

Swage nipples are indispensable in industries such as:

- Oil and Gas

- Petrochemicals

- Power Generation

- Water Treatment Plants

They are highly recommended for systems requiring precise flow control and are essential in applications involving high-pressure fluids.

Choose Riyaarth Overseas for reliable and durable swage nipples tailored to meet your stringent specifications. Contact us today to enhance your operations with our expertly engineered-solutions.

FAQ's

Concentric swage nipples are symmetrical, meaning they taper uniformly towards one end, ideal for maintaining the same centerline or alignment in the piping system. Eccentric swage nipples have one end larger than the other and are used to maintain the same top or bottom level in piping systems, which is essential for drainage and preventing the accumulation of air pockets.

The selection depends on your system’s pressure requirements, the fluid medium, and whether alignment or drainage considerations are a priority. Factors such as material compatibility with the fluid, temperature conditions, and pressure ratings also play crucial roles. We can help guide you through the selection process to ensure optimal compatibility and performance.

Yes, our swage nipples are suitable for high-pressure applications. They are available in various thicknesses and schedules, including Schedule 160 and Double Extra Heavy, which are designed to handle higher pressures. It’s important to match the nipple’s material and thickness to your specific application requirements to ensure safety and durability.

Products

Industry We Serve

- Oil & Gas industries

- Chemical process industries

- Pump and valve in high pressure component

- Food industries

- Pulp and paper industry

- Aerospace industry

- Power plant

- Mechanical component

- Sugar industry

- Cement industry