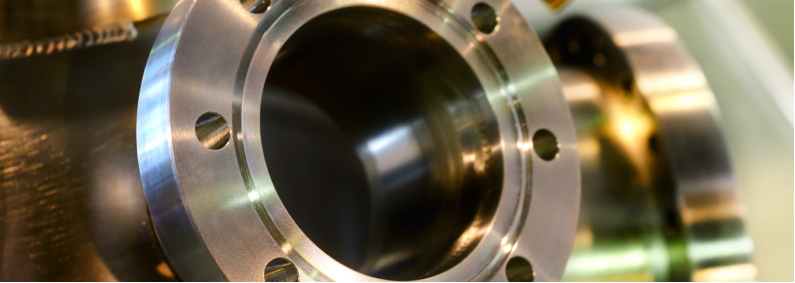

Titanium Flanges

Titanium flanges are highly valued in industries where durability, corrosion resistance, and high performance are essential. They provide reliable, leak-proof connections in challenging environments, including those involving corrosive substances, high temperatures, and high pressures. Titanium’s strength, combined with its lightweight nature, makes it an ideal choice for applications across aerospace, marine, medical, and chemical processing sectors.

Key Benefits of Titanium Flanges

- Exceptional Corrosion Resistance: Titanium resists corrosion from seawater, acids, and industrial chemicals, making it suitable for marine and chemical applications.

- High Strength-to-Weight Ratio: Titanium provides robust strength with a lighter weight compared to other metals, which is valuable in applications where weight reduction is essential.

- High-Temperature Stability: Titanium flanges retain strength and integrity at elevated temperatures, suitable for heat-intensive applications.

- Biocompatibility: Titanium is non-toxic and compatible with the human body, making it an excellent material for medical and food-grade applications.

Types of Titanium Flanges

- Weld Neck Flanges: Ideal for high-stress applications, weld neck flanges offer a strong, seamless connection, welded directly to the pipe.

- Slip-On Flanges: Economical and easy to install, slip-on flanges slide over the pipe and are then welded for a secure fit.

- Blind Flanges: Used to seal the end of a piping system or pressure vessel, blind flanges effectively prevent fluid or gas flow.

- Socket Weld Flanges: Designed for small-diameter, high-pressure systems, socket weld flanges provide a secure fit with only one welded connection.

- Threaded Flanges: Ideal for low-pressure systems, threaded flanges screw directly onto the pipe, eliminating the need for welding.

- Lap Joint Flanges: Commonly used with a stub end, lap joint flanges allow easy assembly and disassembly, beneficial for systems requiring frequent maintenance.

- Orifice Flanges: Often used in flow measurement, orifice flanges feature drilled holes for easy installation of flow meters.

Titanium Grades for Flanges

- Grade 1: Known for excellent formability and corrosion resistance, commonly used in chemical processing and marine applications.

- Grade 2: The most popular grade, offering an ideal balance of strength, corrosion resistance, and weldability.

- Grade 5 (Ti-6Al-4V): High-strength, heat-resistant titanium alloy used widely in aerospace and high-performance applications.

- Grade 7: Titanium alloyed with palladium, providing superior corrosion resistance in aggressive environments.

- Grade 23 (Ti-6Al-4V ELI): Biocompatible and fatigue-resistant, Grade 23 is ideal for medical implants and other surgical applications.

Applications of Titanium Flanges

- Aerospace: Titanium flanges are integral in aircraft hydraulic systems, fuel lines, and structural components due to their lightweight and high-strength characteristics.

- Chemical Processing: Titanium’s resistance to corrosive chemicals makes it ideal for pipes and connections in chemical processing plants.

- Marine and Offshore: Titanium’s resistance to seawater corrosion makes it a reliable choice for seawater cooling systems, desalination plants, and offshore platforms.

- Medical Industry: Titanium’s biocompatibility is essential in medical applications such as surgical implants and dental components.

- Power Generation: Both nuclear and conventional power plants utilize titanium flanges for their durability and resistance to corrosion and high temperatures.

Flange Face Types

We offer titanium flanges in multiple face types to accommodate various sealing requirements:

- Flat Face (FF): Ideal for low-pressure applications, providing a smooth surface for sealing.

- Raised Face (RF): Commonly used in high-pressure systems, providing a strong seal.

- Ring Type Joint (RTJ): Designed for high-pressure, high-temperature applications, with a grooved face that accommodates a metal ring for sealing.

- Male-Female and Tongue-Groove: Provides added sealing strength, suitable for high-stress connections.

Quality Assurance

Each titanium flange is subjected to rigorous quality checks to ensure optimal performance and durability:

- Mechanical Testing: Confirms strength, hardness, and impact resistance.

- Corrosion Resistance Testing: Ensures compliance with industry standards for corrosive environments.

- Dimensional Accuracy: Precision engineering guarantees compatibility and easy integration with piping systems.

FAQs

Yes, titanium flanges are highly durable and resistant to both high-pressure and high-temperature conditions, especially in configurations like weld neck and RTJ.

Industries such as aerospace, chemical processing, marine, oil and gas, and medical benefit greatly from titanium’s lightweight strength and corrosion resistance.

Absolutely. Titanium is biocompatible and non-toxic, making it an excellent choice for medical implants, surgical instruments, and food processing equipment.

Products

Industry We Serve

- Oil & Gas industries

- Chemical process industries

- Pump and valve in high pressure component

- Food industries

- Pulp and paper industry

- Aerospace industry

- Power plant

- Mechanical component

- Sugar industry

- Cement industry