In the world of advanced engineering and high-performance materials, Titanium Grade 5 (Ti-6Al-4V) is widely regarded as the ultimate lightweight alloy. Known for its exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility, this alloy is a top choice across industries like aerospace, medical, automotive, and chemical processing.

Whether you’re researching titanium grades or comparing Grade 23 titanium vs Grade 5, this guide provides a deep dive into Ti-6Al-4V properties, applications, and where to source titanium tubes and fittings in India.

What Is Ti-6Al-4V (Titanium Grade 5)?

Ti-6Al-4V (Titanium Grade 5) is an alpha-beta titanium alloy consisting of 90% titanium, 6% aluminum, and 4% vanadium. The result is a material that retains the lightweight properties of titanium while the addition of the alloying elements adds additional strength when compared to pure titanium. This alloy has a yield strength of 30% and similar corrosion resistance as pure titanium.

It is also referred to by various designations:

- UNS R56400

- AMS 4911

- ASTM B348 (for bars)

| Element | Percentage (%) |

| Titanium (Ti) | Balance |

| Aluminum (Al) | 5.5 – 6.75 |

| Vanadium (V) | 3.5 – 4.5 |

| Iron (Fe) | ≤ 0.40 |

| Oxygen (O) | ≤ 0.20 |

| Carbon (C) | ≤ 0.08 |

| Nitrogen (N) | ≤ 0.05 |

| Hydrogen (H) | ≤ 0.015 |

Ti-6Al-4V Mechanical Properties

| Property | Value |

| Density | 4.43 g/cm³ |

| Tensile Strength | 900 – 1100 MPa |

| Yield Strength | ~830 MPa |

| Elongation at Break | ~10% |

| Modulus of Elasticity | ~114 GPa |

| Hardness (Rockwell C) | 36 – 41 |

| Melting Point | 1604–1660°C |

These properties make Ti-6Al-4V a high-strength titanium alloy and is an ideal material for load-bearing, high-stress, and temperature-sensitive applications.

Where Is Titanium Grade 5 Used?

| Industry | Applications |

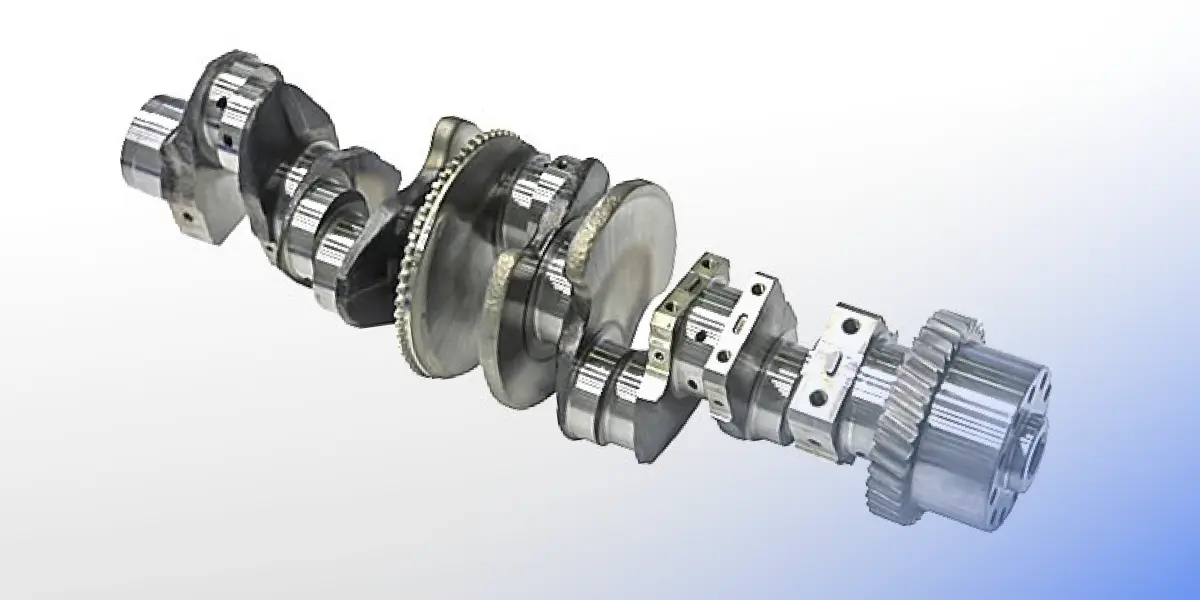

| Aerospace | Engine components, airframes, turbine blades |

| Medical | Bone implants, surgical instruments, dental fixtures |

| Automotive | Performance exhausts, connecting rods, wheel hubs |

| Marine | Offshore components, fasteners, heat exchangers |

| Chemical | Reactors, piping systems, heat exchangers |

Ti-6Al-4V Common Forms of Products

| Form | Standard/Specification | Use |

| Titanium Round Bar | ASTM B348 | Machined parts, shafts |

| Titanium Sheets/Plates | ASTM B265 | Aerospace panels, armor |

| Titanium Fittings | ASME B16.9/B16.11 | Corrosion-resistant pipe connections |

| Titanium Tube | ASTM B338 | Condensers, heat exchangers, surgical tubes |

Ti-6Al-4V vs Other Grades of Titanium

| Feature | Grade 5 (Ti-6Al-4V) | Grade 23 (Ti-6Al-4V ELI) |

| Strength | Higher | Slightly lower |

| Ductility | Good | Better |

| Biocompatibility | High | Superior (used in implants) |

| Oxygen Content | ~0.2% | ~0.13% |

| Typical Use | Aerospace, marine | Medical implants |

Select Grade 5 titanium alloy for performance-driven applications, such as aerospace or marine Select Grade 23 titanium when an implantable component with higher quality and ductility is preferred.

Ti-6Al-4V Density and Strength-to-Weight Advantage

The low density of 4.43 g/cm³ (steel is 7.8 g/cm³) allows the titanium alloy Ti-6Al-4V to be an ideal choice for applications where weight is an issue.

Titanium Grade 5 vs Steel

| Property | Ti-6Al-4V | Stainless Steel (304) |

| Density (g/cm³) | 4.43 | 7.9 |

| Tensile Strength (MPa) | 1000 | 505 |

| Corrosion Resistance | Excellent | Good |

| Cost (Approx.) | Higher | Moderate |

Need High-Performance Titanium Products?

Are you looking for a titanium Grade 5 products like tubes, fittings, or forged bars?

Contact the leading titanium tube suppliers in India for compliance with specifications, such as:

- ASTM B348 and B338 compliant products

- Custom machined & cut products

- Worldwide shipping and MTC documentation

Increase the output of your project with materials that bring maximum strength, corrosion resistance, and lightweight characteristics.

Conclusion

Titanium Grade 5 Ti-6Al-4V is the ultimate lightweight alloy because it exhibits an excellent balance of mechanical strength, low density, and great corrosion resistance. It does not matter whether you are building an aircraft structure, a marine shaft, or a biomedical device: Ti-6Al-4V provided excellent reliability when needed in critical applications.

Use it when failure is not an option, and make sure you partner with certified titanium suppliers in India to ensure quality and performance.

FAQs

High-strength titanium alloys carry excellent corrosion resistance, biocompatibility, lightweight, and thermal stability.

The titanium alloy Ti-6Al-4V density is approximately 4.43 g/cm³, which is near half the weight of stainless steel, and makes it very useable in aerospace applications.

Grade 23 titanium alloy has a lower oxygen level, which gives it better ductility and fatigue strength; as a result, it is preferred for use in biomedical implants, while grade 5 titanium is preferred in aerospace/structural applications.

Many Indian manufacturers provide ASTM B338-compliant tubes and fittings made from high-strength titanium alloys, supplying to global aerospace and defense contractors. Always check for ISO and PED certifications.

Yes, but it requires inert shielding gases (argon/helium) and controlled preheating to avoid contamination and ensure mechanical strength.