Choosing the right stainless steel tube fittings for S355 tubes is crucial for the longevity, safety, and efficiency of any project. Whether you’re working on a structural, mechanical, or industrial application, selecting the correct fittings ensures that the system performs optimally. This guide will walk you through the factors to consider when selecting stainless steel tube fittings for S355 steel, offering expert insights on how to make the best choice for your project.

What is S355 Stainless Steel?

S355 stainless steel is a high-strength, low-alloy steel known for its exceptional durability and resistance to corrosion. Commonly used in structural and manufacturing applications, S355 steel is versatile and well-suited for a range of environments. The designation S355J2 H refers to a specific grade within the S355 family, ideal for applications requiring excellent mechanical properties at high temperatures.

When choosing stainless steel tube fittings, it’s essential to understand the specific characteristics of S355 tube. Its high tensile strength and resistance to corrosion make it ideal for applications involving fluids or gases, where durability and safety are paramount.

Why Stainless Steel Tube Fittings Matter for S355 Tubes?

Stainless steel tube fittings serve a critical function in connecting and sealing S355 stainless tubes, ensuring a secure, leak-free connection. They prevent potential hazards such as leaks or breaks in the system, which can lead to costly downtime or dangerous failures. Without the right fittings, even the highest-quality tube material like S355 steel could underperform, compromising the integrity of the entire system.

When paired with S355 steel tubes, the right tube fittings ensure that the system maintains its strength and resilience over time. The proper fittings allow for efficient fluid and gas flow, minimizing pressure drops and improving system performance.

Types of Stainless Steel Tube Fittings for S355 Tubes

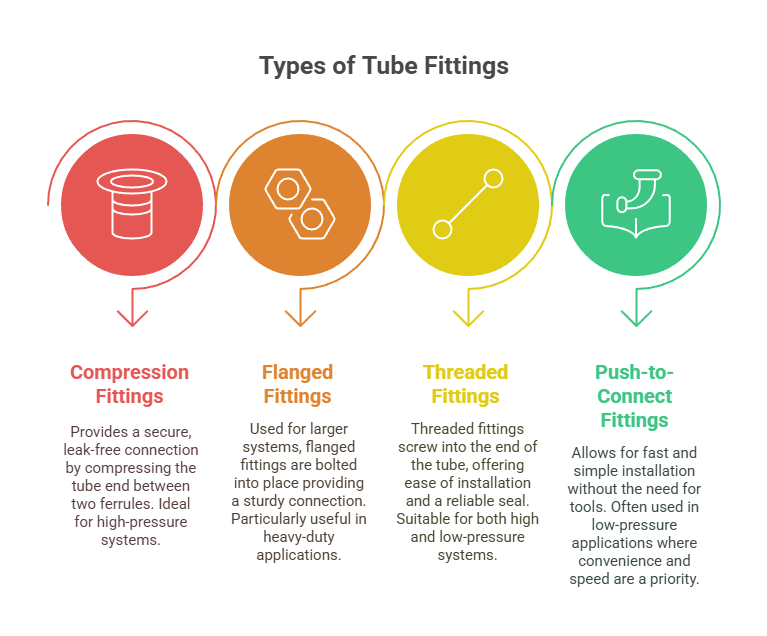

Different applications call for different types of stainless steel tube fittings. Here are some common fittings used with S355 tubes:

- Compression Fittings:

These fittings provide a secure, leak-free connection by compressing the tube end between two ferrules, making them ideal for high-pressure systems. - Flanged Fittings:

Used primarily for larger systems, flanged fittings are bolted into place and provide a sturdy connection, particularly in heavy-duty applications. - Threaded Fittings:

Threaded fittings screw into the end of the tube, offering ease of installation and a reliable seal for both high and low-pressure systems. - Push-to-Connect Fittings:

These fittings allow for fast and simple installation without the need for tools. They are often used in low-pressure applications where convenience and speed are a priority.

Choosing the correct fitting depends on factors such as the pressure requirements, system design, and the specific environment in which the fittings will be used.

Factors to Consider When Choosing Stainless Steel Tube Fittings

When selecting the right stainless steel tube fittings for S355 tubes, several factors must be considered:

- Material Compatibility:

The material of the fitting must be compatible with S355 stainless steel to prevent corrosion or failure. Stainless steel fittings are the best choice due to their resistance to corrosion and high temperatures. - Size and Dimensions:

Ensure the tube fittings match the diameter and wall thickness of the S355 tube. A mismatch in size can lead to leaks and reduced system efficiency. - Pressure Rating:

Consider the pressure requirements of the system. High-pressure systems require fittings designed to handle greater stresses. Compression fittings, for example, are ideal for such applications. - Temperature Resistance:

If the system will be exposed to extreme temperatures, ensure the fittings are rated for high or low-temperature environments, as S355 steel can withstand higher temperatures than many other metals. - Application Type:

Consider the specific application. For instance, if you’re working in an environment with high vibration, choosing vibration-resistant fittings could prevent loosening over time.

By keeping these factors in mind, you can ensure that the stainless steel tube fittings you select provide optimal performance and safety for your S355 steel applications.

Benefits of Choosing the Right Fittings for S355 Tubes

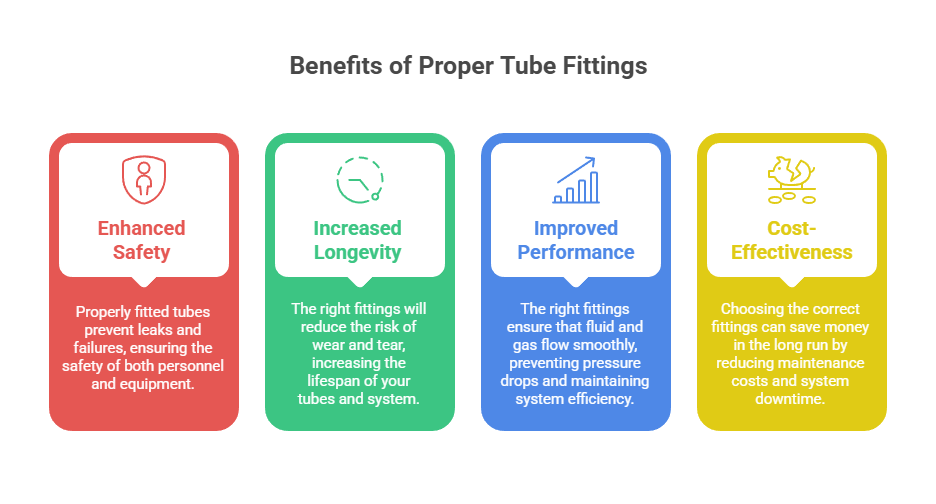

Selecting the right stainless steel tube fittings for S355 tubes offers numerous benefits:

- Enhanced Safety:

Properly fitted tubes prevent leaks and failures, ensuring the safety of both personnel and equipment. - Increased Longevity:

The right fittings will reduce the risk of wear and tear, increasing the lifespan of your tubes and system. - Improved Performance:

The right fittings ensure that fluid and gas flow smoothly, preventing pressure drops and maintaining system efficiency. - Cost-Effectiveness:

Choosing the correct fittings can save money in the long run by reducing maintenance costs and system downtime.

By making the right choice, you not only ensure system performance but also contribute to the overall reliability and efficiency of your project.

Conclusion

Choosing the right stainless steel tube fittings for S355 tubes is a critical decision that impacts the safety, performance, and longevity of your system. Whether you’re working with high-pressure systems, extreme temperatures, or corrosive environments, selecting the appropriate fittings ensures that your S355 steel tubes perform optimally.

Remember to consider material compatibility, size, pressure rating, and application type when making your selection. By following these guidelines, you can choose the best stainless steel tube fittings and ensure a successful and efficient project

FAQs

The best type of tube fitting for S355 steel depends on the specific application. Compression fittings are ideal for high-pressure systems, while flanged fittings work best for larger, heavy-duty applications. Threaded fittings are great for ease of installation in low-pressure systems.

Yes, standard stainless steel tube fittings can typically be used with S355 tubes. However, ensure that the fitting material is compatible with S355 steel to prevent corrosion or wear.

The size of the fitting should match the diameter and wall thickness of the S355 tube. It’s essential to check the tube specifications to choose the correct fitting size for a secure and leak-free connection.

Yes, S355 steel is highly resistant to corrosion, making it suitable for a variety of environments, including marine and industrial applications. However, selecting the right stainless steel tube fittings ensures that the entire system remains durable and secure.

To ensure a leak-free connection, make sure the fittings are properly tightened and that they match the specifications of the S355 tube. Using high-quality, corrosion-resistant stainless steel tube fittings and regularly inspecting the connections can help maintain a leak-free system.