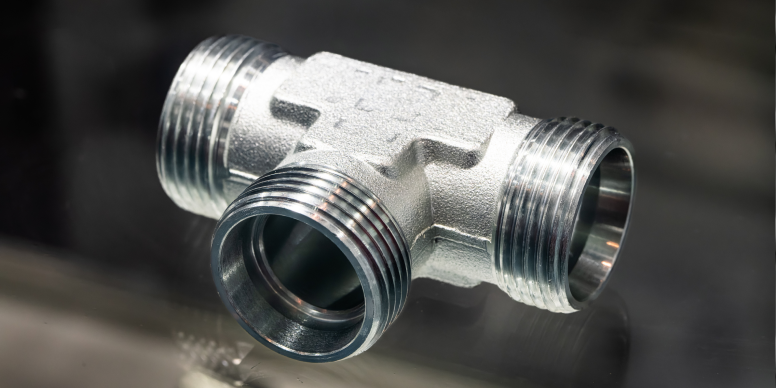

Pipe reducers are fittings used in piping systems that allow two pipes of different diameters to be connected. Pipe reducers allow materials to flow smoothly through the pipe system and also assist with efficiency. Common end-use applications for these fittings include the oil and gas industry, water treatment, and chemical processing.

Let’s understand more about pipe reducers, including their types, materials used to manufacture them, where they are used, and how to choose the right one.

What Are Pipe Reducers?

Pipe reducers are types of fittings that are specifically used to allow two differently sized pipes to connect seamlessly. The joint helps to control the flow of liquids, gases, and other materials through a piping system and assists with keeping an organized, efficient system.

Types of Pipe Reducers

Pipe reducers typically come in two variations:

Concentric Pipe Reducer

A concentric pipe reducer is cut equally on both ends to create a symmetrical design so the centerline of either pipe remains the same. The symmetry allows for a smooth transition of flow. Concentric reducers are excellent for use in a vertical pipe application; symmetrical reductions are best used when targeting a consistent flow, especially in systems protecting some pressure freeze with the process.

Characteristics of a Concentric Pipe Reducer:

- Delivers a balanced flow.

- Very commonly used in pumps in the piping joints.

- Delivers a balanced flow.

- Reduction tumbles; therefore, it is an ideal fit to use with liquids and gases.

Eccentric Pipe Reducer

An eccentric reducer has an offset arrangement where one side is in the same plane as the downstream pipe it is connecting to. This minimizes the risk of liquid pooling and air pockets forming, making it suitable for horizontal pipelines and systems that regularly handle slurries or materials with particulates.

Characteristics of an Eccentric Pipe Reducer:

- Minimizes potential for air pockets in liquid pipelines

- Commonly utilized in drainage and slurry pipelines

- Minimizes noise and vibrations in systems

- Ideal in pipelines with varying flow pressures

Materials Used in Pipe Reducers

- The type of material selected is based on the application and environment.

Carbon Steel

Carbon steel is known for tensile strength and long-lasting durability, so it is often used in high-pressure systems. It is a popular choice in industries when there is a need for durability and reliability in heavy-duty applications.

Stainless Steel

Stainless steel is highly resistant to rust and damage in harsh conditions. It is suitable for environments that require sanitary conditions, such as the food industry, sanitary system,s and chemical industries, and because it is low–maintenance, systems can remain reliable over time.

Alloy Steel

Alloy steel is designed to withstand extreme temperatures and pressures. The material‘s impressive mechanical properties also make it an ideal candidate for challenging industrial applications that require strength and versatility to operate under harsh conditions.

Plastic (PVC, CPVC, HDPE)

Plastic materials, including PVC, CPVC, and HDPE, are lightweight, easy to work with, and often resistant to chemicals and corrosion. As a result, plastics are a favorable option for lower-pressure systems (water distribution), where lower weight, ease of installation, and durability are a concerns.

Copper Alloys

Copper alloys are well recognized for their heat and corrosion resistance, which is why copper alloys are used in HVAC and plumbing systems and are reliable options for transferring heat due to their excellent heat transfer and durability.

Applications of Pipe Reducers

Pipe reducers are versatile and regularly utilized across many industries. Below are some typical applications:

Oil and Gas

Within the oil and gas sector, pipe reducers are an important part of transporting crude oil and natural gas in a piping system. Pipe reducers are used in oil and gas applications and are rated for the higher pressures associated with that application, to facilitate flow from one pressure point to another.

Water Treatment

At water treatment facilities, it is used to regulate the flow inside of water distribution systems. By regulating flow, they ensure that filtration and purification processes operate consistently enough to provide clean water for use.

HVAC Systems

For HVAC systems, this is essential to ensure consistent airflow in heating, cooling, and ventilation systems. Not only do they ensure these systems operate efficiently, but they also aid in improving energy utilization in a proper way, so buildings become more environmentally friendly and economical.

Chemical Processing

In chemical processing, pipe reducers are used to safely transport corrosive materials inside pipelines. They provide smooth transitions between different pipe sizes so that chemicals are transported safely and securely, and to reduce the risk of leaks and/or damage.

Power Plants

In power plants, pipe reducers are used in steam and in cooling water systems. In these vital pipelines, they can manage varying flow rates so that the power plant runs smoothly and without interruption of service, while aiding in the power plant‘s performance depending on the conditions.

Selecting a Reducer

Remember these items when trying to select the correct reducer:

- Flow Requirements: Select concentric or eccentric reducers based on the layout for your system.

- Material Compatibility: Ensure the material can transport the media being transported.

- Pressure and Temperature Ratings: Verify the reducer‘s capabilities for your system.

- Industry Regulations: Look for products that meet ASTM, ANSI, or DIN, which can provide you with guarantees.

Considering these factors will allow you to select a pipe reducer that works smoothly in your piping system.

To see additional choices and high-quality products, visit Riyaarth Overseas or reach out to our experts to get personalized suggestions.

FAQ's

Types of Steel Pipe Reducers: The two main types of steel pipe reducers are conjugate and eccentric, where in conjugate reducers are all the way symmetrical, while in eccentric reducers, the reducers have an offset shape. This is ideal for horizontal systems where you look to avoid a pile–up of fluid.

An eccentric reducer is best when the fluid flow needs to be maintained without air pockets or sediment, which is particularly effective in horizontal pipelines with a system that moves slurry or another particulate-laden product through.

A pipe reducer is used to connect pipes of different sizes, ensuring a smooth flow transition. It helps maintain the efficiency and stability of a piping system by preventing pressure loss and flow disruption between pipes of varying diameters.

The difference between concentric and eccentric pipe reducers is mainly based on their construction. A concentric reducer maintains a vertical alignment between pipe ends and is typically used in vertical pipe systems. An eccentric reducer, on the other hand, has an offset construction designed to reduce the chance of fluids building up in a horizontal piping system.