When selecting materials for harsh industrial environments, super duplex stainless steels like UNS S39274 and UNS S32760 stand out for their excellent corrosion resistance and high mechanical strength. Although these two grades are often used interchangeably, there are critical differences in chemical composition, mechanical performance, and application suitability that can impact long-term operational efficiency.

This guide offers a clear, side-by-side comparison of UNS S39274 vs UNS S32760, helping engineers and procurement teams choose the right alloy for their project needs.

Understanding Super Duplex Stainless Steels

Both UNS S39274 and UNS S32760 belong to the family of super duplex stainless steel grades, known for their dual-phase microstructure of austenite and ferrite. This composition enables high resistance to pitting, crevice corrosion, and stress corrosion cracking especially in chloride-rich or chemically aggressive environments.

Key Chemical Composition Differences

While both alloys offer a high resistance to corrosion, the variation in chemical elements affects their behavior in different applications. Here is the comparison table below:

| Element | UNS S32760 (%) | UNS S39274 (%) |

|---|---|---|

| Chromium | 24.0 – 26.0 | 25.0 – 27.0 |

| Nickel | 6.0 – 8.0 | 6.0 – 8.0 |

| Molybdenum | 3.0 – 4.0 | 3.5 – 4.5 |

| Nitrogen | 0.2 – 0.3 | ≤ 0.3 |

| Copper | 0.5 – 1.0 | - |

| Carbon | ≤ 0.030 | ≤ 0.030 |

| PREN (min.) | 41 – 42 | >42 |

UNS S39274 has slightly higher molybdenum and chromium content, which translates to a higher PREN (Pitting Resistance Equivalent Number), giving it better resistance in seawater and chloride-laden environments.

Mechanical Properties Comparison

| Property | UNS S32760 | UNS S39274 |

|---|---|---|

| Tensile Strength | ≥ 750 MPa | ≥ 750 MPa |

| Yield Strength (0.2%) | ≥ 550 MPa | ≥ 550 MPa |

| Elongation | ≥ 25% | ≥ 25% |

| Impact Strength | > 100 J @ -50°C | > 100 J @ -50°C |

| Hardness (HBW) | ≤ 290 | ≤ 290 |

Mechanically, both grades are nearly identical, but UNS S39274 offers improved corrosion resistance due to its alloying content.

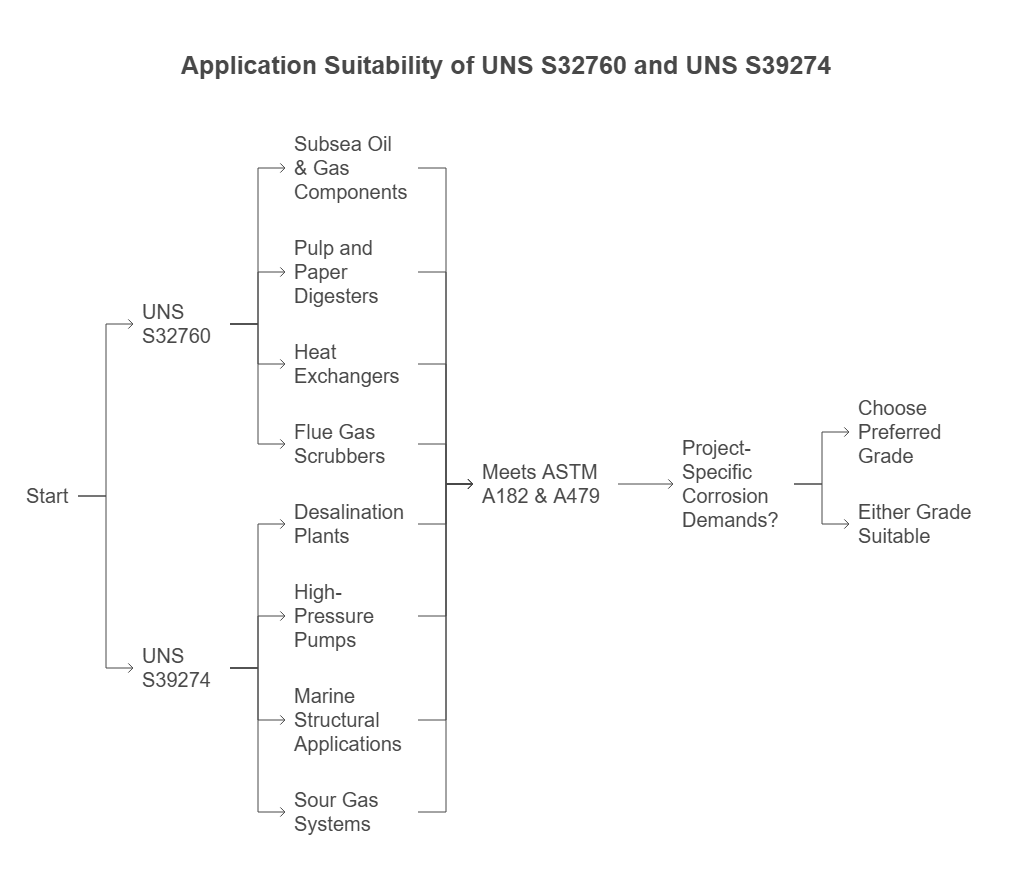

Application Suitability

UNS S32760 is ideal for:

- Subsea oil & gas components

- Pulp and paper digesters

- Heat exchangers

- Flue gas scrubbers

UNS S39274 is best suited for:

- Desalination plants

- High-pressure pumps

- Marine structural applications

- Sour gas systems

Both grades meet ASTM A182 and A479 standards, but project-specific corrosion demands may dictate the preferred choice.

Availability and Supply

Both UNS S39274 and UNS S32760 are available through super duplex stainless steel suppliers in multiple product forms:

- Forged flanges

- Seamless pipes

- Fittings and valves

- Round bars and plates

Choosing the right supplier ensures compliance with international standards and mill test certifications.

FAQs

While both offer excellent performance, S39274 typically has slightly higher corrosion resistance due to increased chromium and molybdenum content.

They are often used in similar applications, but careful review of service conditions and PREN values is necessary before substitution.

UNS S32760 is more commonly stocked globally, but S39274 is growing in adoption for critical environments like desalination and sour service.

Yes, both grades are covered under ASTM A182 and A479 standards for forgings and bars, respectively.